The quality of your electronics is important. We know this, and we make every effort to ensure that the components you receive are of superior quality. Our quality system ensures that technical errors can be found and determines whether it meets our quality compliance. This reduces a customer’s risk of bringing a new product to market.

Our quality procedures and supplier evaluations assist us in selecting the best quality product for you. We do this in a number of ways.

01Electromagnetic Compatibility and Safety Testing

Radiation, conducted interference, electromagnetic radiation durability test, working frequency magnetic field tolerance test, current harmonic test, voltage flicker test, voltage drop tolerance test, electrical fast pulse tolerance test, conduction tolerance test, lightning strike ball resistance tested

02Electrical characteristic testing of other electronic components

1. Parameter test ratio comprehensive evaluation of various discrete devices such as resistance, capacitance, inductance, sensor, relay, speaker, receiver, etc.;

2. Test and comprehensive evaluation of various electrical parameters of connectors and wires;

3. Test and comprehensive evaluation of various electrical characteristic parameters of printed circuit boards;

4. Various electrical parameter tests and comprehensive evaluations of DC power supplies, batteries and battery chargers, and large-capacity farad capacitors;

5. Test and comprehensive evaluation of various photoelectric parameters of LED, LCD screen, touch screen and camera;

6. Test and comprehensive evaluation of various electrical parameters of radio frequency modules and communication modules;

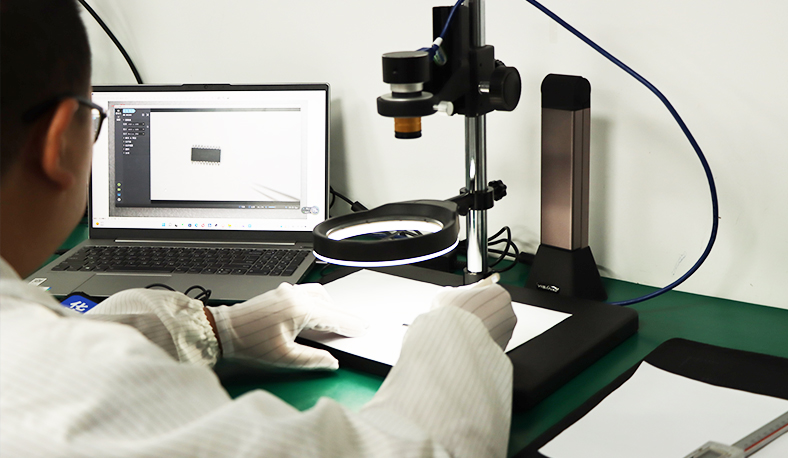

03IC Test Verification

1. MPW proofing (chip sample) phase test program development

Provide packaging design, test board production, test program development and debugging services for IC design companies, and assist IC designers to optimize circuits.

2. Semiconductor back-end foundry service

We provide 4-12 inch wafer testing, thinning, dicing, picking, packaging, testing, tape and other post-processing services. The current monthly production capacity is: 50K for mid-test, 120KK for clearing the line, and 140KK for final testing.

3. Incoming integrated circuit testing and screening service

Level 1, Authenticity Inspection (AIV for short): determine whether the device complies with specified documents or customer-specific requirements;

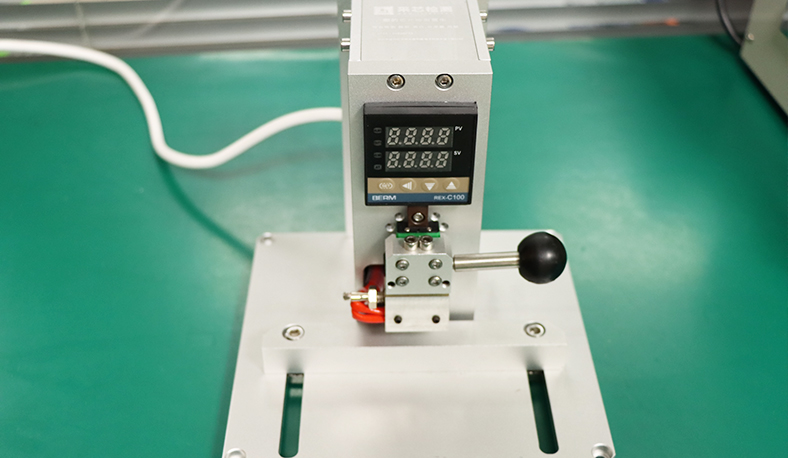

04Testing and analysis of physical properties and material properties

Appearance 3D detection Device size, coplanarity measurement Material thickness measurement Material strength, hardness measurement, pressure resistance, insertion force, push-pull force measurement Magnetic permeability, insulation rate, impedance, inductive reactance, dielectric constant measurement Material qualitative detection Rapid screening and detection of hazardous substances in analytical quantities.

05Electronic components, reliability testing and evaluation

Chip MSL level test and evaluation chip anti-static ability test ratio evaluation electronic components solderability test chip, components and machine life test terminal plug-in endurance test drop, vibration, mechanical shock test Impact test High accelerated stress test High accelerated aging test High pressure, low pressure ratio High altitude environment simulation test Component air tightness test Corrosive gas, liquid ratio Salt spray test Ball peak soldering, reflow soldering process process analysis and evaluation.

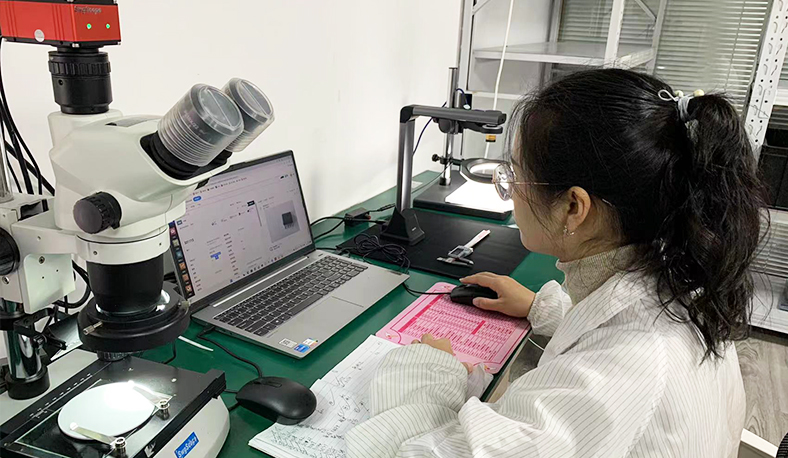

06Chip level, system board level failure analysis

Chip chemistry, laser unsealing and shell removal, chip delamination analysis, chip cross-section analysis, chip hot spot detection, probe penetration into chip internal measurement parameters, board-level red ink test, slice grinding sample preparation, high-power microscope and electron microscope observation, foreign matter Component analysis X-ray detection, CT non-destructive tomography analysis, ultrasonic scanning analysis.